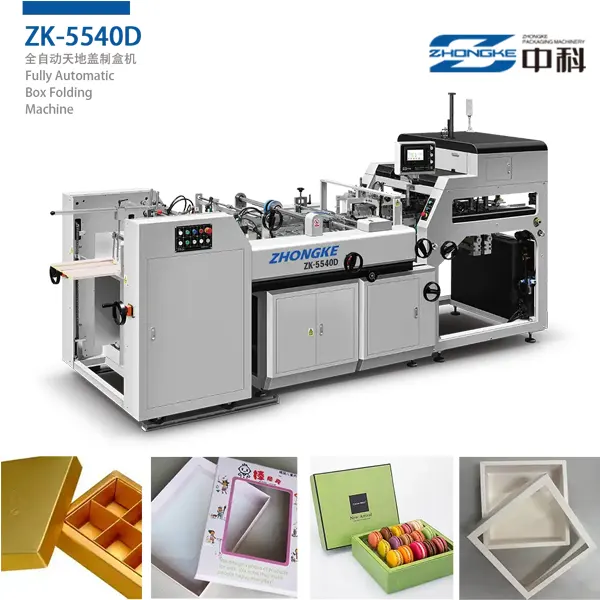

ZK-660FG automatic partial gluing box making machine adopts Germany Beckhoff CX2020 motion controller, Swiss Robatech hot melt glue scraping system, visual manipulator positioning system and touch screen man-machine interface control system. Paper feeding, partial gluing, cardboard four corners taping, positioning and combining, leading, full ear-folding, forming and shaping of the finished product are all automatic.

Features

Suitable for all kinds of automatic rigid box production line.

Automatic suction and conveying of covering paper, cardboard, E and F flute corrugated paper.

Taping machine using separate man-machine interface control system.

Electronic cam and mechanical cam combine to play their respective advantages, makes turn in depth up to 70mm and can adjust freely.

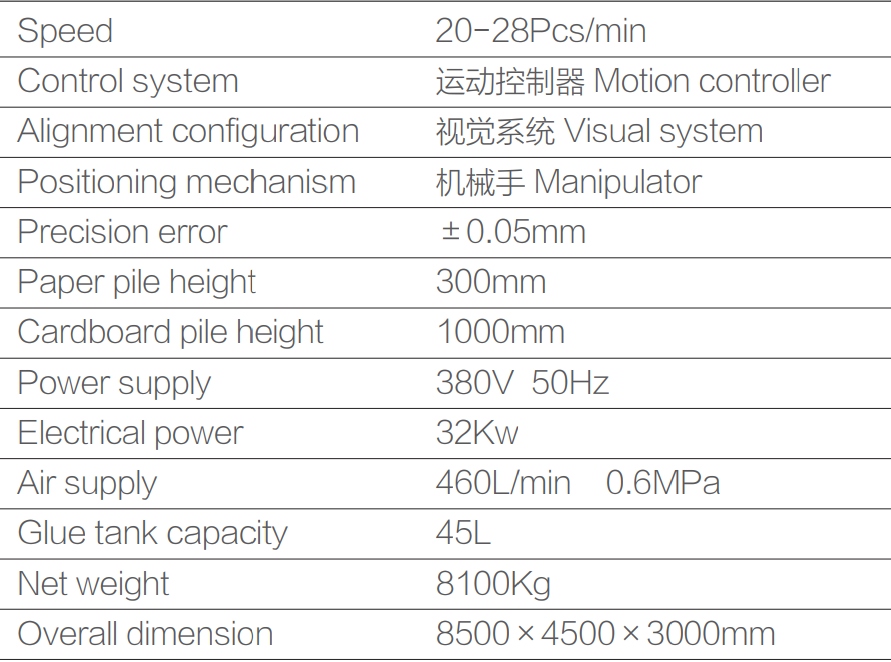

The whole machine adopts Germany Beckhoff CX2020 motion controller as the core control system and touch screen man-machine interface control system.

Visual manipulator positioning (error ± 0.05mm).

Using Swiss Robatech hot melt glue system with PKS250 scraper, the spray surface is thin and even, the partial glue edge is clear.

24-hour control glue preheating function.

Note

The size of the box is restricted by the size of the cover paper;

Online Viscometer system(optional)

The company does not provide air compressors;

Several factors that affect the speed of the machine: raw materials, glue and operator proficiency;

Due to continuous innovation in product design, the above data is for reference only; and are subject to change without notice.

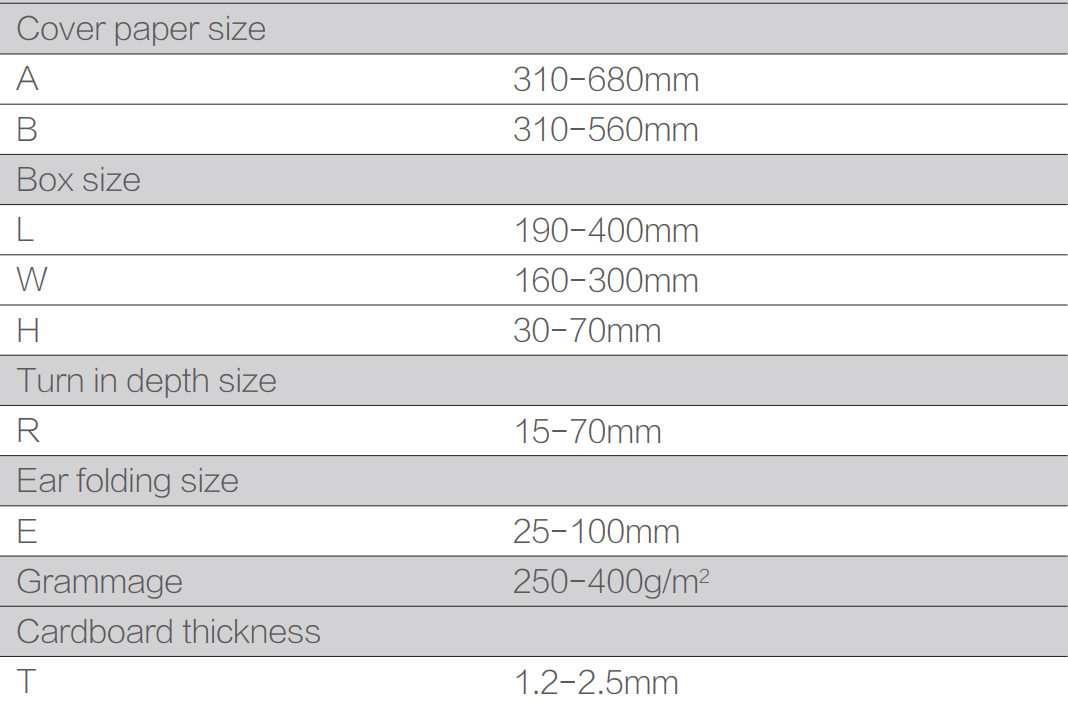

Box Craft Drawing