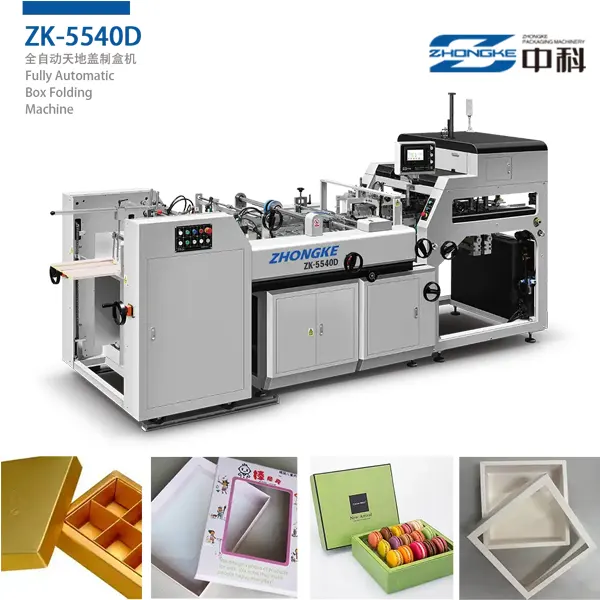

ZK-6421 adopts motion controller, visual manipulator for positioning and human-machine interface intelligent system to realize intelligent operations, digital adjustment and parameterized setting of functions, which make it possible that paper feeding, gluing, cardboard four corners taping, feeding, edge covering, full ear folding, forming and shaping of the finished box are completed in one operation. So it is applicable to the production of high-end rigid boxes, such as business package boxes for electronic products, mobile phone boxes, jewelry boxes, gift boxes, cosmetics boxes and so on.

Features and standard configuration of ZK-6421

Applicable for the production of various rigid boxes.

Automatically sucking covering paper and feeding grey board.

Visually positioning and manipulator capture system (positioning error ±0.05mm).

Automatic box lifting and guiding device.

Using servo motion control, the entire machine is intelligentized to realize the digital adjustment and parameterized setting of functions.

24-hour control of glue preheating.

Sensor is provided for troubleshooting.

Glue viscosity automatic control system (optional).

Unique function of automatic box height adjustment, improving the production efficiency.

Note

The size of the box is restricted by the size of the cover paper;

Glue viscosity automatic control system (optional).

The company does not provide air compressors;

Several factors that affect the speed of the machine: raw materials, glue and operator proficiency;

Due to continuous innovation in product design, the above data is for reference only; and are subject to change without notice.

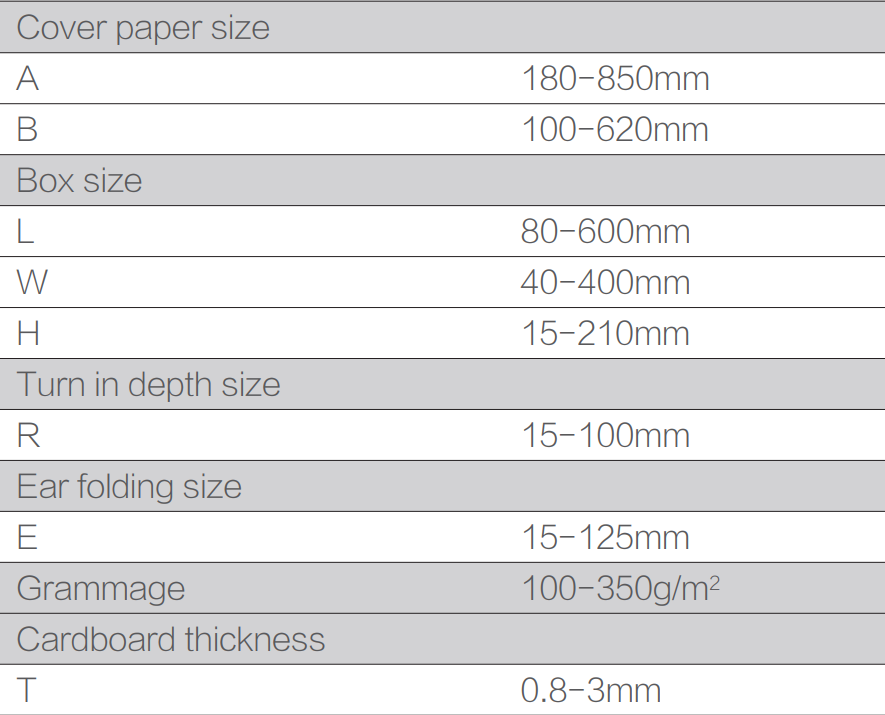

Box Craft Drawing